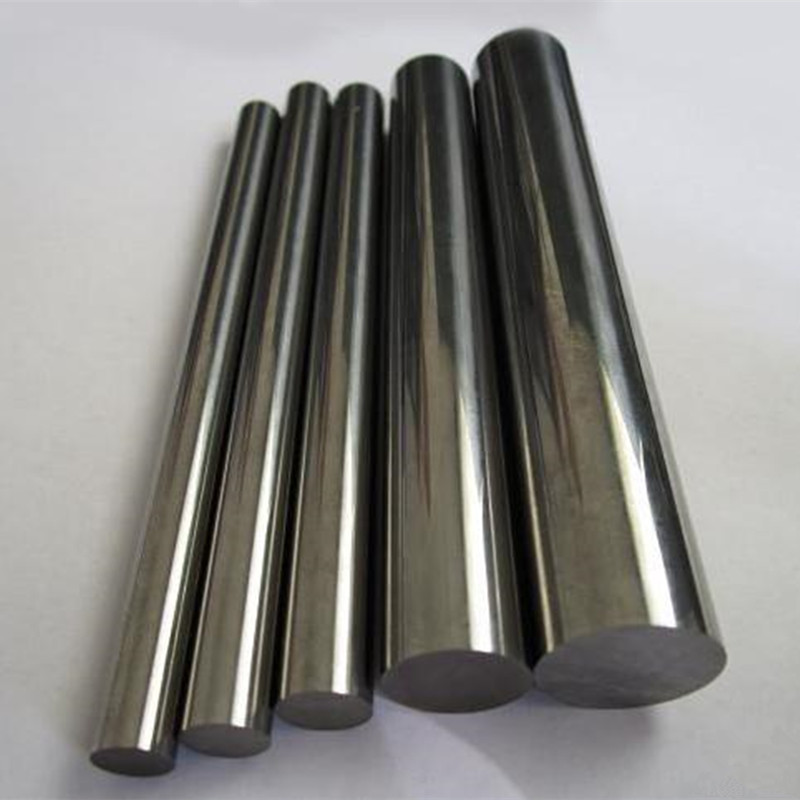

Tungsten Heavy Alloy Rod

Tilmaamaha

Tungsten Heavy Alloy Fasalka:

W90NiFe/W92.5NiFe/W93NiFe/W95NiFe/W97NiFe (wax yar Magnetic).

W90NiCu/W92.5NiCu/W93NiCu/W95NiCu/W97NiCu (aan magnet ahayn).

Cufnaanta:16.8-18.8g/cm3.

Dusha sare:Machined & Dhulka.

Heerka:ASTM B777.

Dhexroorka:5.0mm - 80mm.

Dhererka:50mm - 350mm.

Tungsten High Cufnaanta Alloy Faa'iidooyinka

Cufnaanta sare (ilaa 65% way ka cufan tahay rasaasta).

Qalabka cufan ayaa jira (tungsten saafi ah, Dahab, biraha kooxda platina) laakiin isticmaalkooda waxaa xadiday helitaanka, shaqaynta iyo kharashka.

Bixinta cuf halkaasoo booska mugga uu xaddidan yahay.

Miisaanka xoogga leh ayaa lama huraan u ah halka saxnaanta looga baahan yahay meelaynta cufka.

Meelaynta miisaanka xaaladaha halka socodka hawadu uu saameyn weyn ku leeyahay.

Guryaha kulaylka ee Tungsten Heavy Alloys

Heerkul jilicsan oo sarreeya.

Dhaqdhaqaaqa kulaylka hooseeya iyo isku-dhafka hooseeya ee ballaarinta ayaa siinaya walxaha iska caabin sare oo daalka kulaylka ah.

Iska caabbinta nabaadguurka alxanka heer sare ah ee aluminium dhalaalaysa.Xoog ku leh heerkul sare oo leh xasilooni kulayl sare leh.

Guryaha Farsamaynta Cufnaanta Sare ee Tungsten

● Dhallinta sare ee dabacsanaanta.Ma gurguurto marka ay la kulmaan xoogag muhiim ah, oo ka duwan Lead.

● In kasta oo ay xoog leeyihiin, haddana waxay ahaanayaan kuwo dhuuban oo adkaysi u leh dildilaaca.

● Kala duwanaanta adayga ee daawaha caadi ahaan waa 20-35 Hardness HRC.

Cufnaanta Sare ee Tungsten ku Salaysan

| Nooca Alloy(%) | HD17 90W 6Ni 4Cu | HD17D 90W 7Ni 3Fe | HD17.5 92.5W 5.25Ni 2.25Fe | HD17.6 92.5W Balance Ni, Fe, Mo | HD17.7 93W Balance Ni, Fe, Mo | HD18 95W 3.5Ni 1.5Cu | HD18D 95W 3.5Ni 1.5Fe | HD18.5 97W 2.1Ni .9Fe |

| MIL-T-21014 | Fasalka 1 | Fasalka 1 | Fasalka 1 | - | - | Fasalka 3 | Fasalka 3 | Fasalka 4 |

| SAE-AMS-T-21014 | Fasalka 1 | Fasalka 1 | Fasalka 2 | - | - | Fasalka 3 | Fasalka 3 | Fasalka 4 |

| AMS 7725 C | 7725 C | 7725 C | -- | -- | -- | -- | -- | -- |

| ASTM B777-87 | Fasalka 1 | Fasalka 1 | Fasalka 2 | - | - | Fasalka 3 | Fasalka 3 | Fasalka 4 |

| Cufnaanta Caadiga ah(g/cc) | 17.1 | 17.1 | 17.5 | 17.6 | 17.7 | 18 | 18 | 18.5 |

| Cufnaanta Caadiga ah(lbs/in3) | 0.614 | 0.614 | 0.632 | 0.636 | 0.639 | 0.65 | 0.65 | 0.668 |

| Adag ee caadiga ah RC | 24 | 25 | 26 | 30 | 32 | 27 | 27 | 28 |

| Ugu Dambeyntii Xoog Xasilloonida Min(ksi) | 110,000 | 120,000 | 114,000 | 120,000 | 125,000 | 110,000 | 120,000 | 123,000 |

| 0.2% Wax-soosaarka Xoog-saarka Min(ksi) | 80,000 | 88,000 | 84,000 | 90,000 | 95,000 | 85,000 | 90,000 | 85,000 |

| Ugu yaraan % Dheeraynta(1 "dhererka dhererka) | 6 | 10 | 7 | 4 | 4 | 7 | 7 | 5 |

| Xadka Laastikada Saami-lahaan(PSI) | 45,000 | 52,000 | 46,000 | 55,000 | 60,000 | 45,000 | 44,000 | 45,000 |

| Qaabka Elasticity(x106psi) | 40 x 106 | 45 x 106 | 47 x 106 | 52 x 106 | 53 x 106 | 45 x 106 | 50 x 106 | 53 x 106 |

| Isku-dhafka Balaadhinta kulaylka x10-6/0C(20-400C) | 5.4 | 4.61 | 4.62 | 4.5 | 4.5 | 4.43 | 4.6 | 4.5 |

| Habdhaqanka kulaylka(Cutubyada CGS) | 0.23 | 0.18 | 0.2 | 0.27 | 0.27 | 0.33 | 0.26 | 0.3 |

| Waxqabadka Korontada(% IACS) | 14 | 10 | 13 | 14 | 14 | 16 | 13 | 17 |

| Magnetik | No | Wax yar | Wax yar | Wax yar | Wax yar | No | Wax yar | Wax yar |