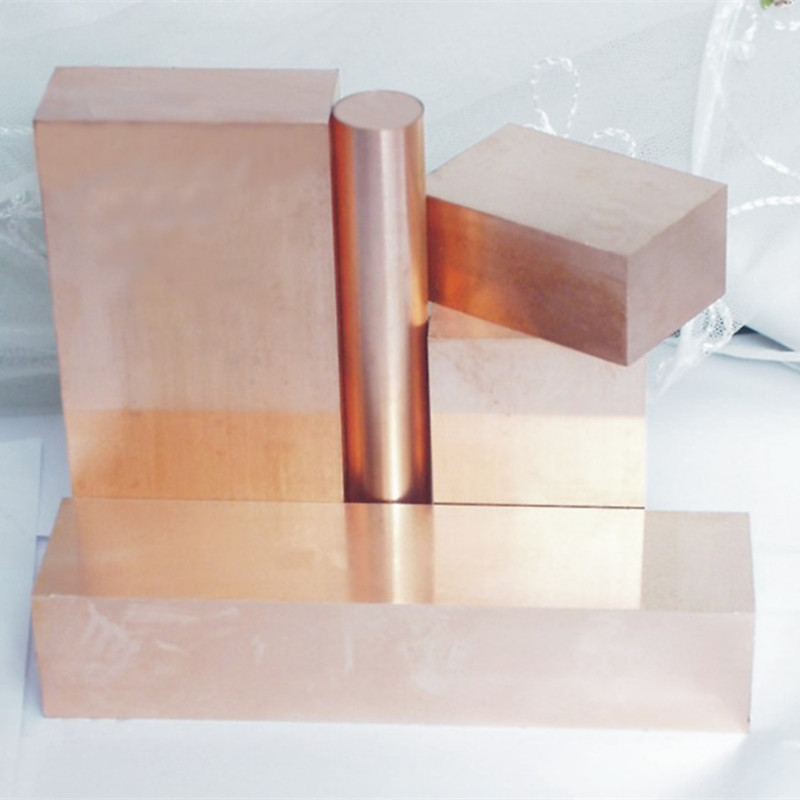

Alloy Tungsten Copper Alloy (WCu Alloy)

Sharaxaada Iyo Tilmaamaha

Sharaxaad:

Daawaha naxaasta Tungsten waxaa laga samayn karaa ulo, taarikada iyo qalab kale oo la farsameeyey si waafaqsan codsiyada macaamiisha. Si ballaaran loo isticmaalo sida xiriirka korantada, electrodes, weelka kulaylka iwm.

Tilmaamaha:

Tungsten Copper Alloy Fasalka:

W50Cu50, W60Cu40, W65Cu35, W70Cu30, W75Cu25, W80Cu20, W85Cu15, W90Cu10.

Cufnaanta:11.8-16.8g/cm3.

Dusha sare: Machined & Ground.

Ulaha Tungsten Copper: Dia (10-60)mm x (150-250)mm L.

| Koodhka No. | Halabuurka Kiimikada % | Guryaha makaanikada | ||||||

| CU | wasakhnimo≤ | W | Cufnaanta(g/cm3 )≥ | AdagHB≥ | RES(μΩ·cm)≤ | Hab-dhaqankaIACS / %≥ | TRS/ Mpa≥ | |

| CuW(50) | 50± 2.0 | 0.5 | Dheelitiran | 11.85 | 115 | 3.2 | 54 | |

| CuW(55) | 45±2.0 | 0.5 | Dheelitiran | 12.30 | 125 | 3.5 | 49 | |

| CuW(60) | 40± 2.0 | 0.5 | Dheelitiran | 12.75 | 140 | 3.7 | 47 | |

| CuW(65) | 35± 2.0 | 0.5 | Dheelitiran | 13.30 | 155 | 3.9 | 44 | |

| CuW(70) | 30± 2.0 | 0.5 | Dheelitiran | 13.80 | 175 | 4.1 | 42 | 790 |

| CuW(75) | 25± 2.0 | 0.5 | Dheelitiran | 14.50 | 195 | 4.5 | 38 | 885 |

| CuW(80) | 20± 2.0 | 0.5 | Dheelitiran | 15.15 | 220 | 5.0 | 34 | 980 |

| CuW(85) | 15± 2.0 | 0.5 | Dheelitiran | 15.90 | 240 | 5.7 | 30 | 1080 |

| CuW(90) | 10± 2.0 | 0.5 | Dheelitiran | 16.75 | 260 | 6.5 | 27 | 1160 |

Copper Tungsten Alloy Faa'iidooyinka

1. U adkaysiga kulaylka wanaagsan;

2. Iska caabbinta ka fiican;

3. Xoog badan.

4. Cufnaanta sare;

5. kulaylka iyo korantada aad u fiican;

6. Fudud in lagu farsameeyo.

Codsiga Daawaha Copper Tungsten

Tungsten copper (Cu-W) Alloy waa isku-dhafka tungsten iyo copper kaas oo leh waxqabadka ugu wanaagsan ee tungsten iyo copper. Waxaa si weyn looga isticmaalaa warshadaha sida mishiinka, korontada, elektarooniga, biraha, duulimaadka hawada iyo duulista.

1) Xidhiidhada qashin-qubka iyo xidhiidhka vacuum ee jebiyayaal danab sare iyo mid dhexe ah ama dhex-geliyaasha faakuumka

2) Electrodes ee mashiinada goynta nabaad guurka koronto

3) Kuleylku wuxuu noqdaa walxo qaboojin aan fiicneyn oo ah aaladaha elektiroonigga ah

4) Electrodes for Resistance Welding.