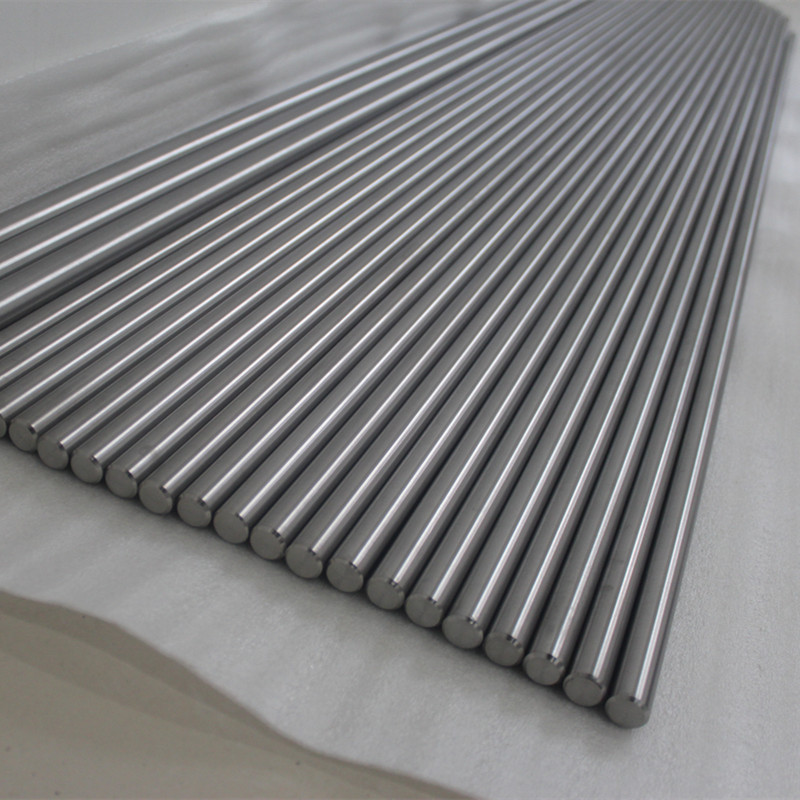

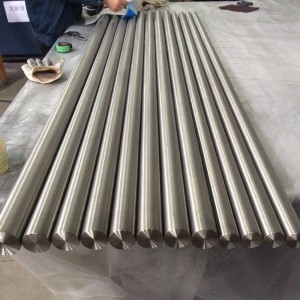

Titanium Rod Titanium Alloy Bar

Sharaxaada

Usha Titanium waa alaabta ceeriin ee loo isticmaalo in lagu sameeyo daawaha titanium iyo birta titanium. Waxay leedahay sifooyinka cufnaanta hoose, xoogga sare iyo caabbinta daxalka wanaagsan. Warshadaha hawada sare, usha titanium ayaa si weyn loogu isticmaalaa soo saarista qaybaha qaab dhismeedka diyaaradaha iyo gantaalada gantaalada; warshadaha kiimikada, waxa loo istcimaalaa sida koriyaha iyo qalab sifaynta ee electrolytes; warshadaha mishiinada, waxaa loo isticmaali karaa sidii kulaylka iyo kondenser.

Warshadaha birta, ul/bar titanium waxaa inta badan loo isticmaalaa in lagu soo saaro bir saafi ah oo kala duwan, bir aan-xawaag lahayn, birta kulaylka u adkaysata iyo birta daawaha gaarka ah. Intaa waxaa dheer, waxaa sidoo kale loo isticmaalaa soo saarista dhagaxyada macmalka ah iyo kiristaalo rutile zircon, xaashida dhoobada piezoelectric ee warshadaha elektiroonigga ah, iyo dhejinta saxda ah ee qaabab kala duwan.

Cad Titanium Rod / Titanium Alloy Bar Tilmaamaha

Titanium Alloy Fasalka:Gr.5, Gr.23, Ti-6Al-4v-Eli, TI5, BT6,Ti-6al-7Nb.

Qiimaha Titanium ganacsi saafi ah:Gr.3, Gr.4 ganacsi ahaan saafi ah.

Dhexroorka dhexroorka:Ø5mm, Ø6mm, Ø8mm, Ø12mm, Ø14mm, Ø25mm, Ø30mm, iwm.

Heerka Dulqaadka:ISO 286.

Heerka:ASTM F67, ASTM F136, ISO 5832.

Dhererka la heli karo:2.5 m ~ 3 m (98.4 ~ 118.1"), ama la habeeyey.

Toosanku habboon mashiinka CNC.

Dhammaan baararka Titanium iyo Titanium Alloy ulaha/baararka waxaa lagu keeni karaa dhexroor ama dherer la habeeyey, si ay ugu habboonaato shuruudaha macmiilka.

Tilmaamaha ulaha alloy titanium:Laastiig heer sare ah, xoog sare iyo qaab-dhismeed yar oo isku mid ah.

Darajada Titanium waa la heli karaa

| ASTM B265 | GB/T 3620.1 | JIS H4600 | Waxyaabaha curiye (wt%) | ||||||

| N,Max | C,Max | H,Max | Fe, Max | O, Max | Kuwo kale | ||||

| daahirTitanium | Gr.1 | TA1 | Fasalka 1 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | - |

| Gr.2 | TA2 | Fasalka 2 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | - | |

| Gr.3 | TA3 | Fasalka 3 | 0.05 | 0.08 | 0.015 | 0.30 | 0.35 | - | |

| Gr.4 | TA4 | Fasalka 4 | 0.05 | 0.08 | 0.015 | 0.50 | 0.40 | - | |

| TitaniumAlloy | Gr.5 | TC4Ti-6Al-4V | Fasalka 60 | 0.05 | 0.08 | 0.015 | 0.40 | 0.20 | Al:5.5-6.75;V:3.5-4.5 |

| Gr.7 | TA9 | Fasalka 12 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | Pd:0.12-0.25 | |

| Gr.11 | TA9-1 | Fasalka 11 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | Pd:0.12-0.25 | |

| Gr.23 | TC4 ELI | Fasalka 60E | 0.03 | 0.08 | 0.0125 | 0.25 | 0.13 | Al:5.5-6.5;V:3.5-4.5 | |