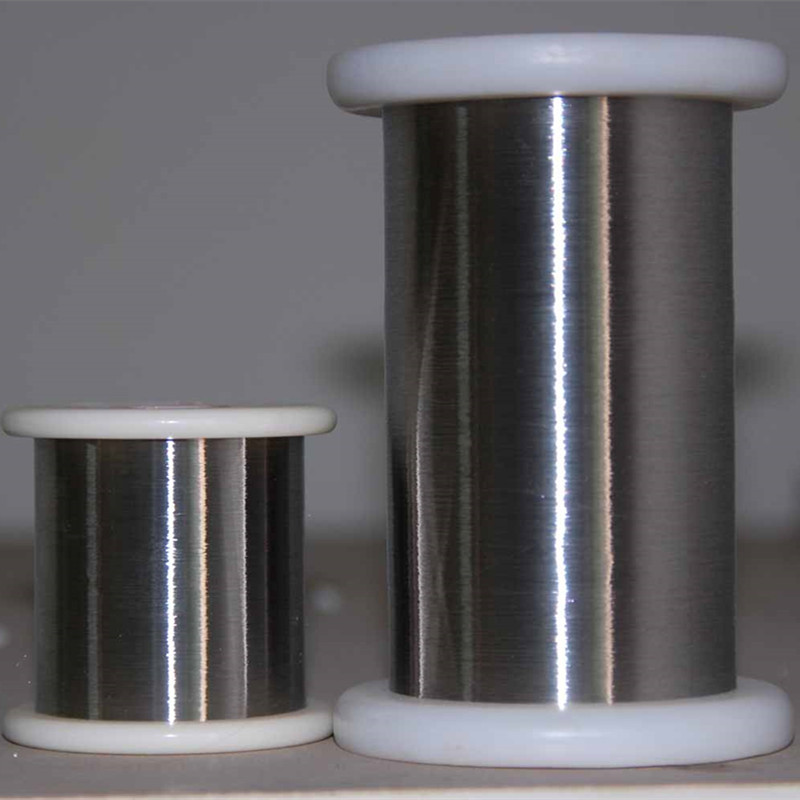

Nickel Chromium NiCr Alloy Wire

0.03mm Wire NiCr Alloy, 637 MPA Nickel Chromium Wire Kululiyaha, Ni90Cr10 NiCr Alloy

Ni90Cr10 waa austenitic nikkel-chromium alloy ku habboon codsiyada heerkulka ilaa 1250 ° C. Maadada chromium sare (30% celcelis ahaan) waxay bixisaa waqti aad u wanaagsan nolosha, gaar ahaan codsiyada foornada, waxaa inta badan loo isticmaalaa vape, sida walxaha kuleylka.

Ni90Cr10 waxaa lagu gartaa iska caabin sare, iska caabin oksaydh wanaagsan, ductility wanaagsan ka dib isticmaalka iyo alxanka heer sare ah. Daawaha kuma xidhna " qudhunka cagaarka ah " oo si gaar ah ugu habboon dhimista iyo oksaydheynta jawiyada.

Ni70Cr30 waxaa loo isticmaalaa walxaha kululaynta korontada ee foornooyinka warshadaha. Codsiyada caadiga ah waa: foornooyinka korantada iyo dhaldhalaalka, kuleyliyeyaasha kaydinta, foornooyinka iyo kilnnada jawiga isbeddelaya.

Codsiyada NiCr Alloy Wires:

Walxaha nickel-chromium waxay leeyihiin xoog heerkul sarreeya iyo caag adag.

Si ballaaran loo isticmaalo foornooyinka korontada ee warshadaha, qalabka guriga, qalabka fog-infrared.

Nickel-chromium iyo birta, aluminium, silicon, carbon, sulfur iyo walxo kale ayaa laga samayn karaa silig nikkel-chromium alloy ah oo leh adkaysi sare iyo iska caabin kulaylka. Waa curiyaha kuleyliyaha korontada ee shooladda korontada, birta alxanka korontada, birta korontada, iwm.

Faa'iidooyinka Nikel-Chromium Wire:

Iska caabintu waa mid aad u sareysa, lakabka dusha sare wuxuu leeyahay iska caabin oksaydh ah oo wanaagsan, iyo xoogga cadaadiska ayaa lagu hayaa si ka fiican kan fiilada birta-chromium-aluminium ee hoos yimaada heerkulka heerkulka sare ee deegaanka dabiiciga ah, iyo hawlgalka heerkulka sare ma fududa in la soo saaro qallafsanaanta. Siligga Nickel-chromium waxa uu leeyahay qallafsanaan caag ah oo wanaagsan, sifooyin wax-qabad oo aad u wanaagsan iyo karti-u-qoris, fududahay in la soo saaro oo la farsameeyo, fududahay in la hagaajiyo oo ay adag tahay in la beddelo qaab-dhismeedka. Intaa waxaa dheer, siligga nikkel-chromium waxay leedahay qiiqa hawada sare, caabbinta daxalka wanaagsan iyo muddada codsiga dheer.

Miisaska waxqabadka alloy ee nickel-chromium

| Waxqabadka | Cr10Ni90 | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 | |

| Halabuurka | Ni | 90 | Naso | Naso | 55.0-61.0 | 34.0-37.0 | 30.0-34.0 |

| Cr | 10 | 20.0-23.0 | 28.0-31.0 | 15.0-18.0 | 18.0-21.0 | 18.0-21.0 | |

| Fe |

| ≤1.0 | ≤1.0 | Naso | Naso | Naso | |

| Heerkulka ugu badan ℃ | 1300 | 1200 | 1250 | 1150 | 1100 | 1100 | |

| barta dhalaalaysa ℃ | 1400 | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Cufnaanta g/cm3 | 8.7 | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| iska caabin |

| 1.09±0.05 | 1.18±0.05 | 1.12 ± 0.05 | 1.00±0.05 | 1.04±0.05 | |

| μΩ·m,20℃ | |||||||

| Dheeraynta markay dillaacdo | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | |

| Kuleyl gaar ah |

| 0.44 | 0.461 | 0.494 | 0.5 | 0.5 | |

| J/g.℃ | |||||||

| Dhaqdhaqaaqa kulaylka |

| 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| KJ/mh℃ | |||||||

| Isku-dhafka fidinta khadadka |

| 18 | 17 | 17 | 19 | 19 | |

| a×10-6/ | |||||||

| (20~1000 ℃) | |||||||

| Qaab dhismeedka micrographic |

| Austenite | Austenite | Austenite | Austenite | Austenite | |

| Guryaha magnetic |

| Aan magnet ahayn | Aan magnet ahayn | Aan magnet ahayn | Magnet daciif ah | Magnet daciif ah | |